Under-road cavity exploration services

- Keyword

Overview

In recent years, numerous reports of road collapses have occurred across the country. While large-scale road collapses are relatively rare, small-scale subsidence occurs frequently. To prevent such incidents, it is crucial to assess the underground cavity conditions in advance and implement appropriate measures.

By utilizing exploration vehicles equipped with ground-penetrating radar to detect cavities under roads, OYO Corporation provides a service to prevent cave-ins through non-destructive methods.

Features

Causes of Cavity Formation

One of the causes of cavities forming beneath the road is the aging of buried pipes, such as sewer and stormwater pipes. When there is a break in the pipes or at the joints, soil can flow into the pipe, leading to the formation of cavities. As soil collapses into these cavities, they expand and gradually rise to the surface. This results in a thinning of the soil cover, which can ultimately lead to a collapse.

Flow of Soil into a Pipe from a Breakage in the Pipeline

Cavity Exploration Using Ground-Penetrating Radar

The "ground-penetrating radar" used in our subsurface cavity exploration service emits electromagnetic waves downwards from the road surface. By analyzing the reflected waves, this technology estimates the locations of cavities and buried pipes. It enables an efficient assessment of cavity conditions over a broad area without damaging the road.

- Contents of the Subsurface Cavity Exploration Service

-

- Investigation of the location, size, and depth of cavities

- Estimation of the causes of formation

- Prediction of future hazard levels

- Suggestions for remedial measures

Furthermore, our company leverages extensive knowledge gained as a geology and geotechnical consultant to provide estimates of cavity formation causes, hazard predictions, and recommendations for countermeasures.

Process of Cavity Exploration

The process begins with a subsurface cavity exploration vehicle equipped with ground-penetrating radar that drives along a wide section of the roadway to assess conditions beneath the surface. The data collected is then analyzed to identify any "anomalous signals" that may indicate the presence of cavities.

If such signals are detected, a handheld radar device is used for a more detailed examination of those specific areas. If the follow-up evaluation still suggests the possibility of a cavity, an on-site drilling investigation is performed to check for the presence of cavities directly.

Subsurface Cavity Exploration Vehicle Capable of Traveling at 80 km/h

Our company owns a specialized exploration vehicle called the "Road Visualizer," designed to efficiently assess cavity conditions beneath the road. It can travel at a maximum speed of 80 km/h while rapidly collecting data at 2.5 cm intervals.

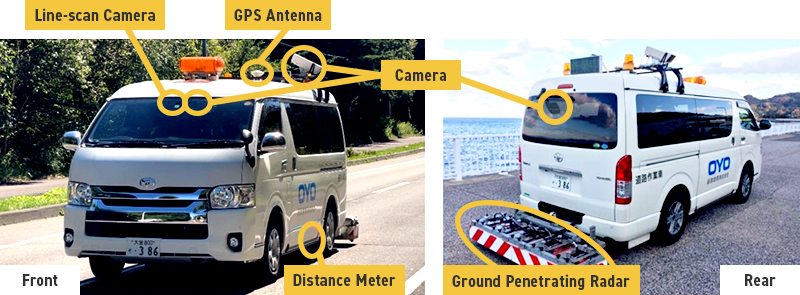

Additionally, the vehicle captures video while in motion, equipped with GPS antennas and distance meters. It also has a line-scan camera at the front and video cameras at the front, rear, and sides. the vehicle captures video footage while in motion, equipped with GPS antennas, distance meters, and line-scan and video cameras mounted on the front, rear, and sides. This allows for the collection of information about pavement conditions and manholes. By combining radar exploration results with camera footage, we can significantly enhance the accuracy of cavity assessment and identification of their causes.

- Vehicle-Mounted Subsurface Cavity Investigation System: Road Visualizer (NETIS: KT-170089-A)

-

[Estimated Investigation Length per Day] - Urban Areas: Approximately 15 km/day

- Suburban Areas: Approximately 20 km/day

- By combining data from ground-penetrating radar and line-scan cameras, the location of anomalous signals that may indicate cavities can be clearly defined in relation to the road surface.

- The line-scan camera offers a high resolution, allowing it to read inscriptions on manholes (e.g., "Sewage").

- The camera can also check for cracks or other surface irregularities near the anomalous signals, enabling us to provide more accurate investigation results.

AI-Powered Cavity Detection with 100% Recall Rate

The automatic cavity analysis technology using AI (artificial intelligence) has been developed ahead of the industry and is currently in operation within this service. The extensive measurement data collected while driving is analyzed by AI in almost real-time, achieving a 100% recall rate for cavity detection.

By utilizing AI, not only is the accuracy of investigations improved but the time required for cavity analysis is significantly reduced. This contributes to the earlier implementation of countermeasures and helps reduce the risk of accidents caused by sinkholes.

Support for Estimating Causes, Predicting Risk Levels, and Proposing Countermeasures

Cavities often result from factors such as the deterioration of aging pipelines; however, various soil characteristics can also contribute to cavity formation. To prevent accidents like sinkholes, it is essential not only to identify the location of cavities but also to accurately estimate their causes and the potential risks moving forward. Taking appropriate countermeasures based on this assessment is crucial for effective risk management.

- OYO At a Glance

- Top Message

- Management Philosophy and Management Vision

- Code of Conduct

- Various Policies

- Corporate Profile

- OYO's History

- Directors & Executive Officers

- Organization Chart

- Group Companies

- List of Offices

- Medium-Term Business Plan

- DX Initiatives

- R&D

- Information on Company Certifications