Infrastructure maintenance field20230403

System for tunnel inspection, maintenance, and management

Field:

Infrastructure Maintenance, Management, and Renovation > Infrastructure maintenance field

Keyword:

Overview

In accordance with Japan's Ministry of Land, Infrastructure, Transport and Tourism ordinances based on the Road Act, road administrators such as the national government and local

governments are obligated to carry out close-up visual inspections once every five years to diagnose the soundness of road tunnels.

In tunnel inspections, it is common to use

an aerial work platform to check for abnormalities in the lining concrete by close-up visual inspection and hammering inspection. When using this method, the abnormal points are

marked and recorded in hand-drawn sketches. However, since this method is performed for the entire tunnel, it requires human wave tactics and a large amount of time. Furthermore,

the work was prone to human errors such as differences in workers' skills, oversights, and omissions in records. Consequently, there was a need to increase efficiency and improve

quality.

OYO Corporation uses digital technologies such as AI and point cloud data to increase the efficiency and sophistication of inspection work, and to improve the quality of results.

Features

Increased sophistication and efficiency of tunnel inspection

During inspections, OYO Corporation also uses a 3D tunnel laser measurement system with an installed laser scanner to acquire high-density 3D data and record inspections by AI image

analysis based on that data. As a result, we were able to improve the quality of inspection results and the sophistication of diagnostics.

Prior to close-up inspection, we use self-propelled measurement to extract the deformation points. This increases the efficiency of close-up visual inspection and hammering inspection,

and shortens the work time, thereby minimizing the impact of traffic restrictions on vehicle traffic.

3D modeling of structures by 3D laser scanners

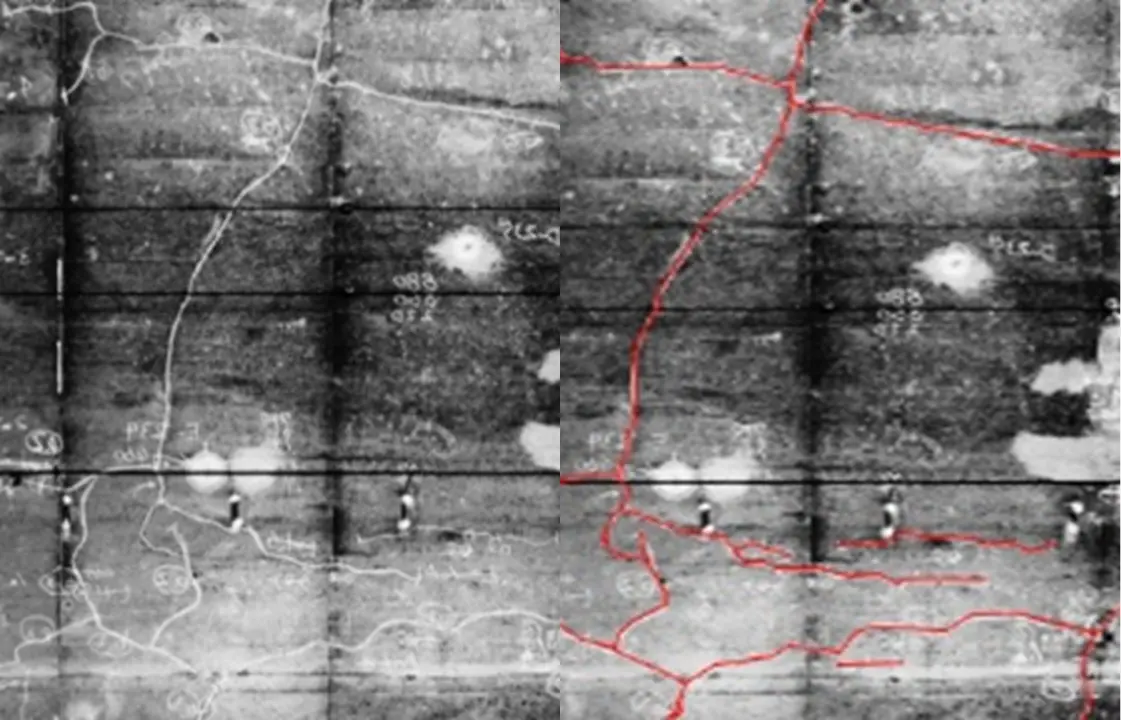

Extraction of cracks by AI

MAGIS-CIM: Integrated information system for 3D data and inspection results

The 3D data and inspection results are incorporated into the 3D integrated information system MAGIS-CIM together with construction information, etc., in order to construct BIM /

CIM.

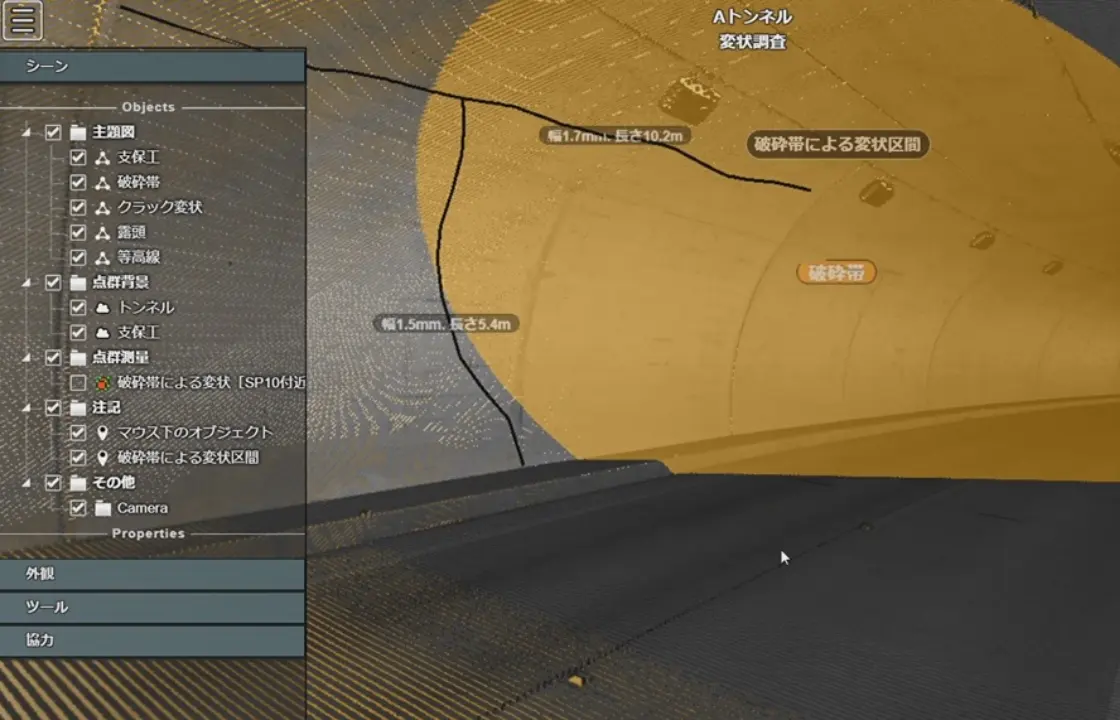

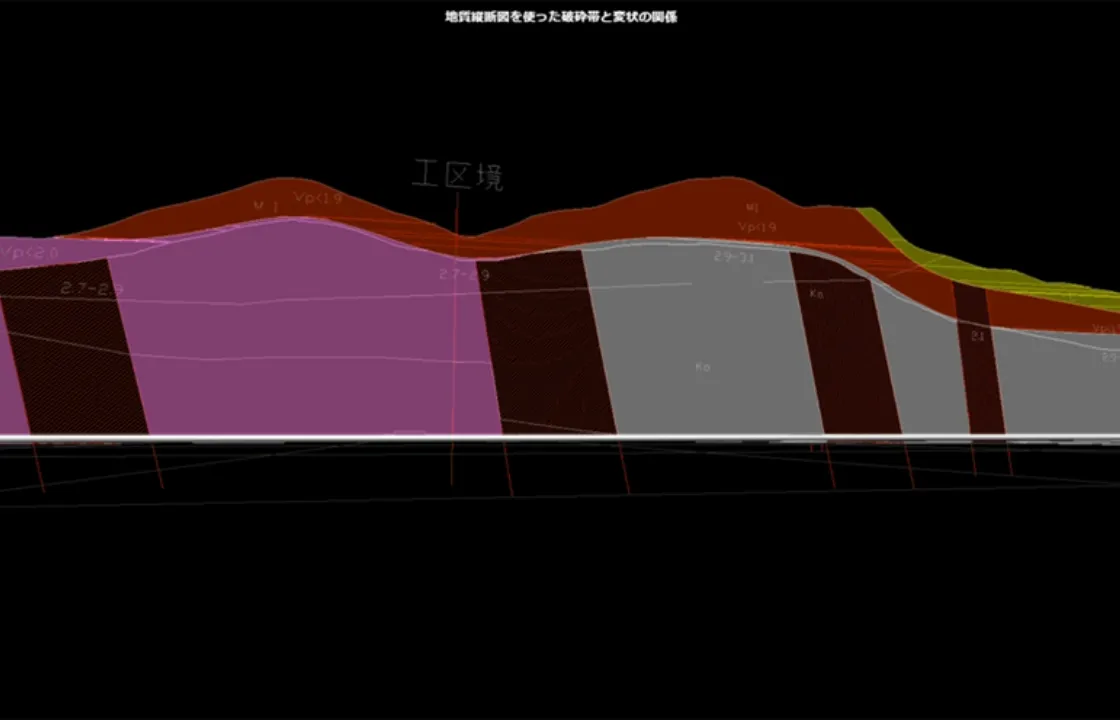

MAGIS-CIM reproduces topography and geological information around the tunnel and deformation conditions inside the tunnel in a 3D space. The system can determine the external force

acting on the tunnel and the range where deformation may occur. This makes it possible to appropriately designate reinforcements for certain sections.

Superimposition of deformation points and surrounding geology on the 3D model

Relationship between deformation and fracture zones using geological profile